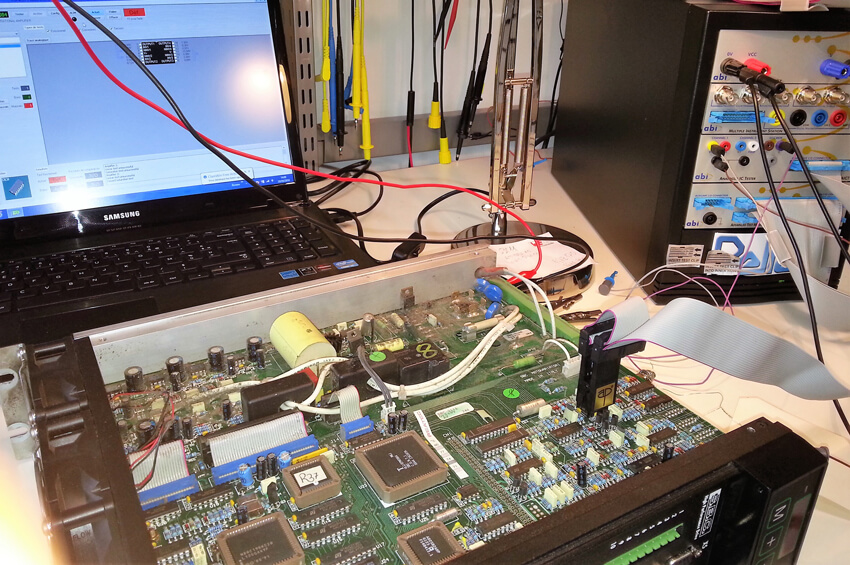

Electronic hardware repair: Take advantage of the latest generation of in-situ component test benches.

Our electronics repair technicians use the latest and most efficient testing equipment.

For functional testing:

- Three phase power 380 / 220 V

- Motors for testing variable speed/frequency drives

- 7 kW resistive load for testing DC power supplies

- Lab power supplies

- Oscilloscope

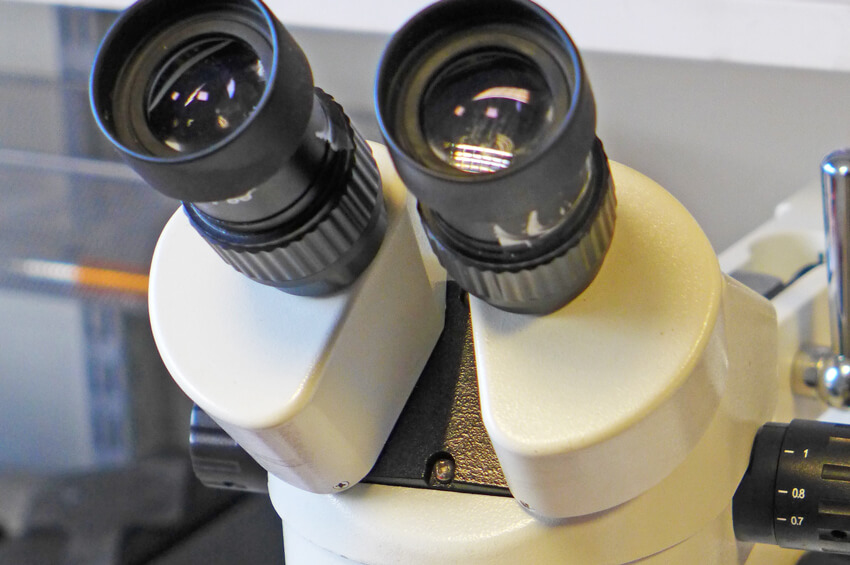

- Binocular vision equipment

- Multiple component reading/programming devices(PROM, PAL, microcontrollers,…)

To repair equipment, our technicians use the latest generation of in-situ component test bench that allows them to check all components of an electronic board.

IN-SITU component tests conducted using our test bench, latest generation

Digital components*:

- In-situ functional testing of TTL, CMOS, LVTTL, ECL, DTL, RTL, PECL, LVPECL, memories, interfaces, LSI, microprocessors in DIL, SOIC, PLCC, QFP packages in compliance with the US Department of Defense standard

- Control of connections, voltages, logic levels, internal component temperature, V/I signature analysis

Analog components*:

- Opto-couplers, data converters, transistors, triacs, thyristors in dynamic functional test (V/T)

- Connection and voltage testing

- Dynamic Analog Signatures Analysis (ASA) mainly intended for analog power boards (power supply boards for example), equipped with Triacs, Thyristors, transformers, large capacitors, inductors etc.

- Accurate detection of micro-cuts and short circuits by milliohm meter.

*The names, brands and signs mentioned on this site are the property of their respective depositors.