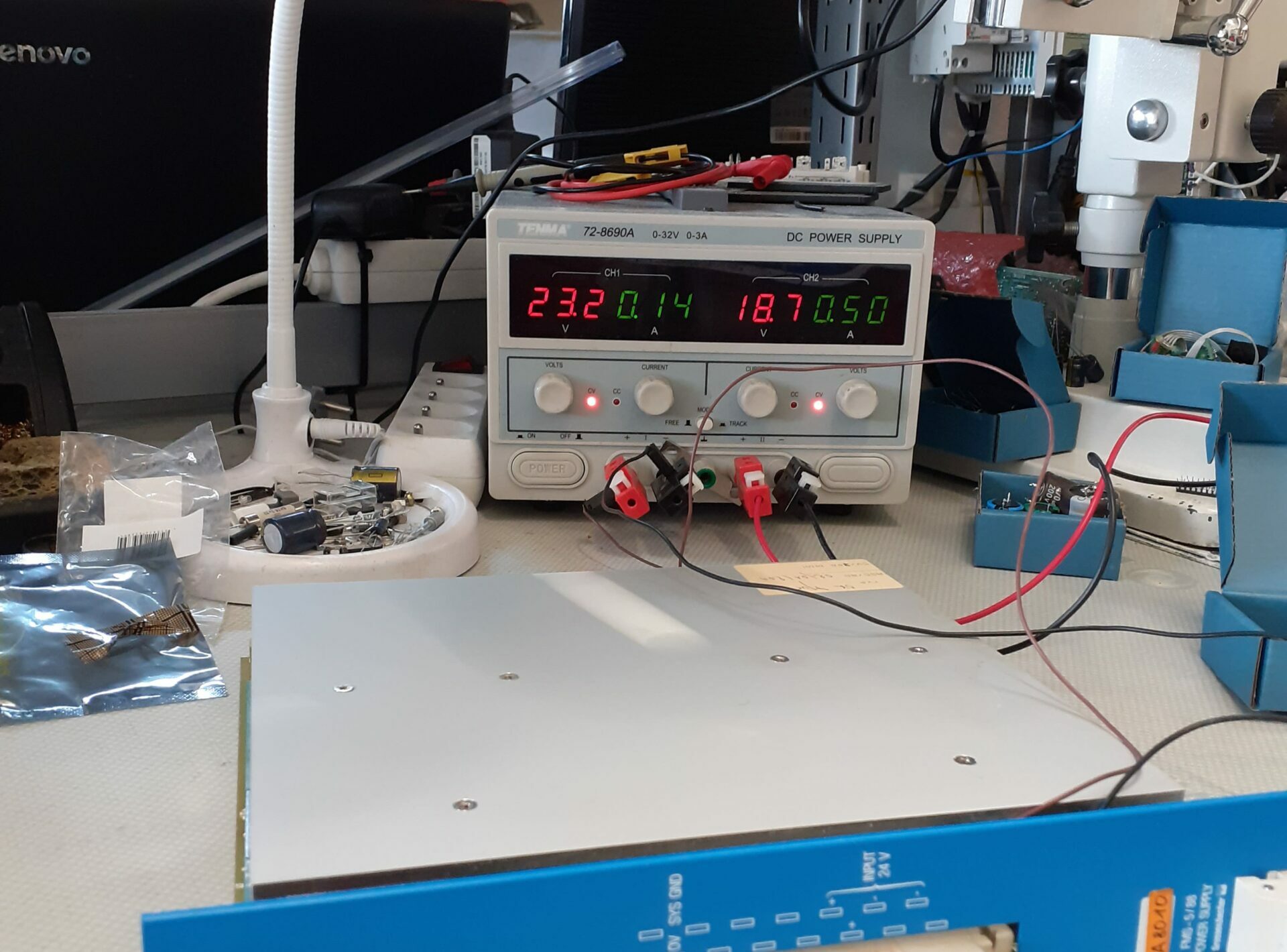

Basic troubleshooting equipment

Our technicians are equipped with all the basic equipment necessary for the electronic repair activity: Soldering station, desoldering pump, multimeter, ESR-meter, binocular vision device, laboratory power supply, 380/220V three-phase power supply, 7kw resistive load, test motors for variable speed drive, oscilloscope.

Each technician has a personalized space corresponding to 4.5 meters of linear space and a PC for sharing technical documents, accessing the collaborative tool for monitoring repairs and searching for any relevant and necessary information.

Each technician has a personalized space corresponding to 4.5 meters of shelf space and a PC for sharing technical documents, accessing the collaborative tool for monitoring repairs and searching for any relevant and necessary information.

The test benches entrusted by our customers

Our customers frequently entrust us with their test benches so that our technicians can carry out repairs and validate them in accordance with the specifications provided and the defined repair process.

We take particular care in the storage and maintenance of the various benches entrusted to us and in the management of the documentation relating to their operation.

Example of the Paragon test bench: test bench for magnetic ticket encoding cards.

Maintenance of the Dassault Systèmes technology.

Advanced equipment

- In addition to the basic troubleshooting equipment, our

technicians use recent and efficient testing means

performing test equipment:- An in-situ component test bench – concept 8000+

- Devices for reading / programming of components

(PROM, PAL, microcontrollers) - Gausscope probe for electric current analysis

– unique tool designed and developed by E-NERGIE.

The 8000+ test bench

Digital components:

- In-situ functional tests of TTL, CMOS, LVTTL, ECL, DTL, RTL, PECL, LVPECL, memories, interfaces, LSI, micro processors in DIL, SOIC, PLCC, QFP packages in compliance with the US Department of Defense standard.

- Control of connections, voltages, logic levels, internal temperature of the component,

- V/I signature analysis

Analog components :

- Optocouplers, data converters, transistors, triacs, thyristors in dynamic functional test (V/T)

- Control of connections and voltages

- Dynamic Analysis of Analog Signatures (ASA) mainly intended for analog power boards

(power supply boards for example), equipped with Triacs, Thyristors, - Precise detection of micro-cuts and short circuits by milliohm-meter.

Work environment : Security - Access control

- E-NERGIE brings a particular care to the safety and the cleanliness

during repairs and interventions. - Each technician regularly receives the necessary PPE for the

necessary for the realization of his work. - Outside opening hours, the workshop is secured thanks to

an alarm and video surveillance system to maintain the integrity

the integrity of the premises and protect the equipment entrusted to us.